Automation is transforming industries worldwide, and wastewater treatment is no exception. With increasing environmental regulations, population growth, and the pressure to conserve water, the demand for more efficient and cost-effective wastewater treatment solutions is rising. Automation offers a range of benefits that make it indispensable in modern wastewater management.

1. Enhanced Efficiency and Precision

1. Enhanced Efficiency and Precision

Manual processes are prone to errors and inefficiencies. Automated systems can monitor water quality, flow rates, and chemical levels with precision, ensuring that the treatment process remains consistent. Sensors and control systems can detect anomalies in real-time, allowing for immediate adjustments. This reduces the risk of human error and enhances overall operational efficiency.

2. Cost Savings

2. Cost Savings

Automation reduces the need for a large workforce to monitor and manage systems manually. While the initial investment in automated systems may be significant, long-term operational costs are considerably reduced. By optimizing energy use and reducing waste, plants can achieve significant savings in operational expenses over time.

3. Improved Compliance with Regulations

3. Improved Compliance with Regulations

Regulatory bodies impose strict guidelines for wastewater discharge. Automated systems ensure that treatment plants consistently meet these regulations by providing real-time data monitoring and control. Automated reporting systems can also simplify compliance audits, reducing the risk of non-compliance penalties.

4. Better Resource Management

4. Better Resource Management

Automation can help plants optimize the use of chemicals and other resources. By precisely measuring and delivering the right amount of treatment chemicals, water treatment plants can minimize excess usage and reduce environmental impact. This leads to better resource management and a more sustainable treatment process.

5. Increased Safety

5. Increased Safety

Wastewater treatment involves handling hazardous chemicals and managing potentially harmful waste. Automated systems can perform these tasks with minimal human intervention, reducing the risk of accidents and exposure to dangerous substances. Automated safety protocols can also respond to emergencies faster than manual systems, ensuring the safety of both workers and the environment.

6. Real-time Monitoring and Data Collection

6. Real-time Monitoring and Data Collection

Automated systems allow for continuous monitoring and data collection, providing valuable insights into plant performance. This data can be analysed to identify trends, inefficiencies, and opportunities for improvement. Predictive maintenance becomes easier as systems can alert operators before equipment failures occur, minimizing downtime and maintenance costs.

7. Scalability for Growing Demands

7. Scalability for Growing Demands

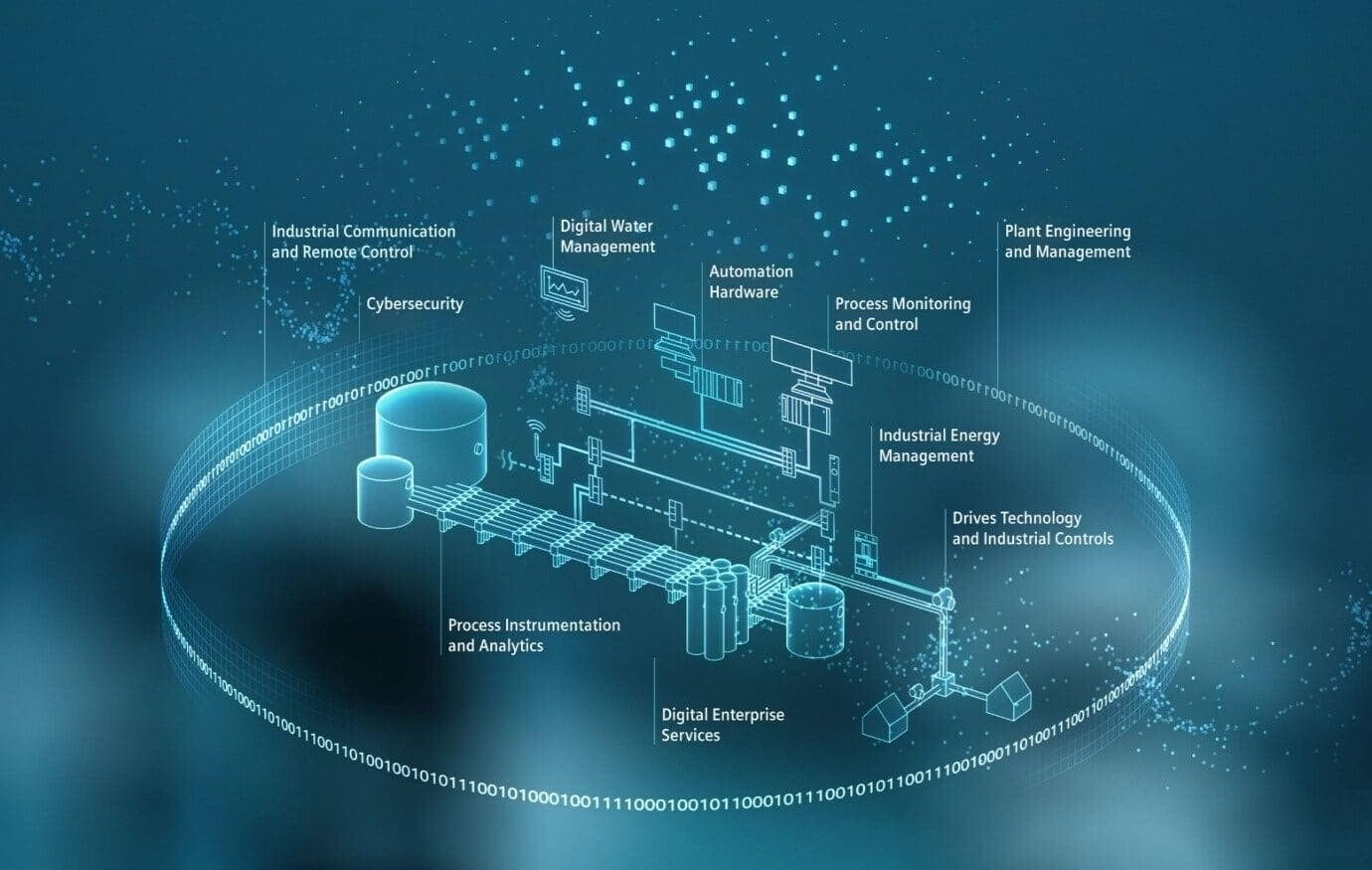

As urban areas expand and industrial activities increase, the demand for efficient wastewater treatment also grows. Automation allows wastewater treatment plants to scale operations efficiently, managing higher capacities without a significant increase in labour or resource input. Here are some leading companies providing automation and real-time monitoring solutions for industrial wastewater treatment plants:

1. Endress+Hauser 2. Rockwell Automation

3. ABB 4. Siemens

5. Bentley Systems 6. Wipro Water

7. Yokogawa 8. Jumo

9. Larsen & Toubro 10. Emerson

Conclusion

Conclusion

The integration of automation in wastewater treatment is no longer a luxury but a necessity. It enhances operational efficiency, reduces costs, ensures compliance with regulations, and supports a safer, more sustainable approach to wastewater management. As the industry evolves, automation will play a crucial role in meeting the growing challenges of water conservation and environmental protection.